Screening

Safe products due to well-proven screening technology

Reliable screening of raw materials before, during or after production is essential for the quality of your end products. Depending on the industry and raw material, there are different requirements that must be met. With our wide range of AZO screening machines, you can meet them without any problems. Ultrasonic screeners with inert gas supply for handling highly reactive "divas", easy-to-clean cyclone screeners for hygienic screening of "weaklings" or feeding hoppers with integrated vibrating screen for lumpy "stubborn brats" - we have the right solution for you.

Find out more

Prescreening during product feeding

The feeding hopper has an integrated vibrating sieve and coarse material discharge. Control screening takes place as soon as the product is fed in. Foreign particles are retained and automatically discharged.

Find out more

Control screening in pneumatic conveying streams

The TW 650 type screening machine is used for control screening in closed pneumatic conveying streams. It is often installed between the silo vehicle and the storage silo when filling silos. This ensures that no coarse impurities or lumps enter the production.

Find out more

Cyclone screener type E

Control screening, breaking up of lumps, separation of agglomerates and foreign bodies, as well as loosening of powders are the standard tasks of the type E cyclone screener. It can be fed in a dosed manner via an airlock or dosing screw or, as here, pneumatically in the conveying stream.

Find out more

Cyclone screener type E in combination with metal separators

AZO cyclone screeners combine functionally reliable technology with high performance as well as easy maintenance and cleaning. Due to their compact design, the screening machines can be easily integrated into existing plants.

For the separation of ferrous and paramagnetic ferrous contaminants from 25 µm, a magnetic grate can be installed downstream of the screening machine. This can also separate fine iron abrasion from stainless steel pipes, which occurs in the production process when the austenitic steel has been converted into magnetic alpha-martensite.

Safe products due to AZO eddy current screening technology:

- Compliance with IFS standard and HACCP.

- Automatic separation of foreign particles

- Clean and safe end product

Cyclone screener type DA

The cyclone screener type DA for control and protective screening, fractionation, separation of foreign bodies, breaking up of lumps and loosening of products, works without an additional dosing element. It therefore has a low overall height and can thus be easily integrated into existing systems. Other advantages include easy opening of the machine without tools and pull-out and swivel devices for the screen and metering screw, so that the screen basket and screw can be easily inspected and cleaned. The dead spaces in the machine have been minimized, further improving cleanability. The screen basket can be replaced effortlessly via a quick-change system

Find out more

Screening and dosing in one device

The cyclone screener type DA combines the functions of screening and dosing. Integrated into a small container filling and weighing station, it enables the safe and flexible filling of products into different container shapes.

Find out more

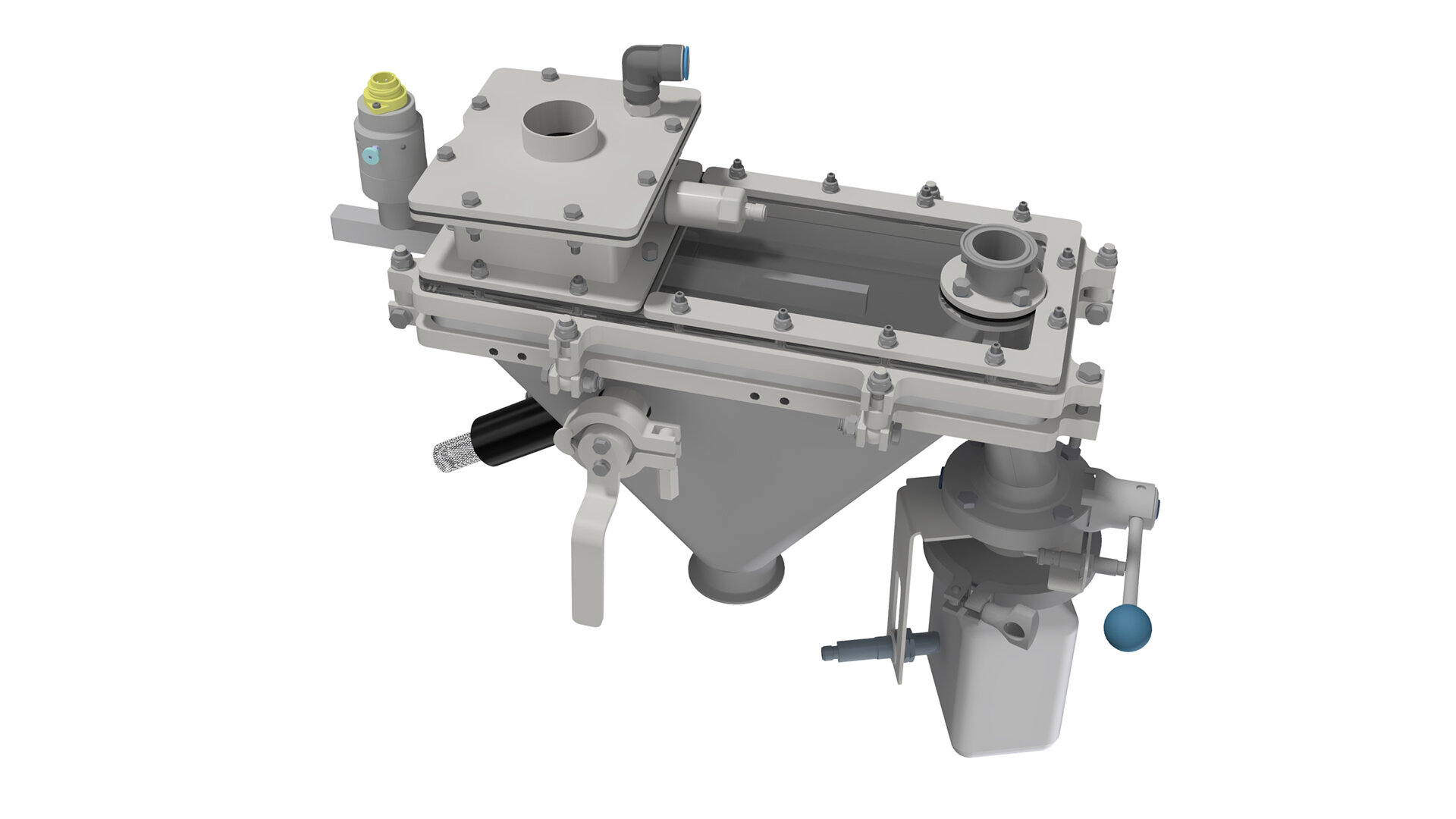

Separation of solids from liquids

Ausscheiden von Feststoffen aus Flüssigkeiten

AZO cyclone screener type FLF is used for continuous separation of solids from liquids e.g.

- Cheese dust from whey

- butter from buttermilk

- fruit residues

- control screening in latex and paint production

- Preclarification of waste water in environmental protection

- Stirring of powders into liquids

- Recovery of solids from liquids

- Separation of solid chemicals from waste water

- Removal of residues from waste oils

Screening of metal powders

The UFS 765 ultrasonic screener was specially developed for screening metal powders when feeding 3D metal printers. Metal powder fed in is screened before being conveyed to the 3D printer and coarse material contained is separated out.